Face Masks

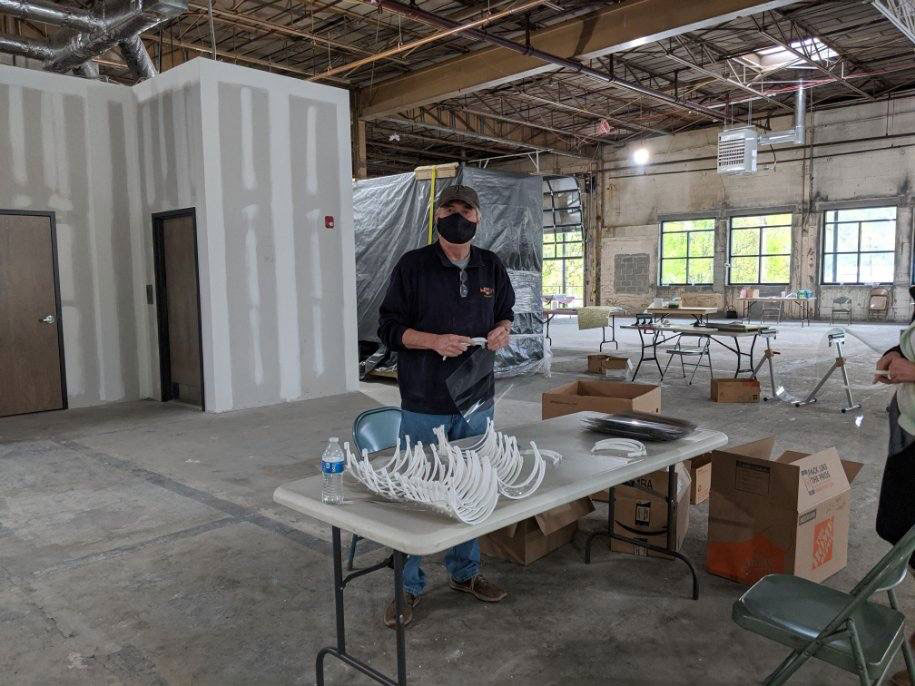

In conjunction with the Temple University COVID-19 Task Force and in a partnership with the Temple University College of Engineering, ChariTdi is established temporary worksites to manufacture face shields, which ultimately were distributed to Temple University Hospital to help meet a critical shortage of Personal Protection Equipment, also known as PPE. As an industry partner, ChariTdi replicated many of the production methods executed by the on-campus task force. Temple donated equipment and materials to ChariTdi to perform this manufacturing.

There are two primary components of the face shield – 1) the head band and 2) the plastic shield. ChariTdi was involved in both components.

TDI helped to develop a liquid plastic mold process which was capable of producing large numbers of face shields in a short amount of time.

As a result, ChariTdi was able to produce a mass number of PPE during a critical shortage for health care workerers in Philadelphia during the height of the COVID-19 Pandemic.